Biofabrication: Working on the front line

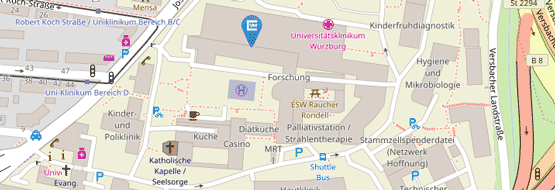

07/07/2016They develop artificial tissues set to revolutionize the future of medicine: Three students from Australia. Enrolled in the international master's programme "Biofabrication", they are currently spending two semesters in Würzburg where they are doing research in the laboratories on Röntgenring.

"We are definitely working on the front line of an exciting development and I am thrilled to have the opportunity to work with leading scientists in this field." "In this field" refers to a comparably young domain of research that is currently making headlines with keywords such as "tissue engineering" and "biofabrication". And the "we" refers to three students from Australia enrolled in the new "Biofabrication" programme which the University of Würzburg is offering jointly with the universities in Utrecht (the Netherlands), Wollongong and Brisbane (Australia).

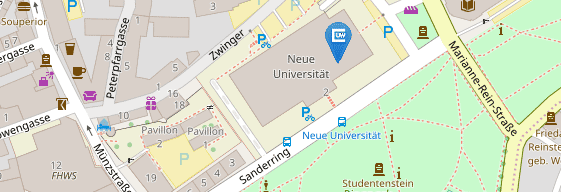

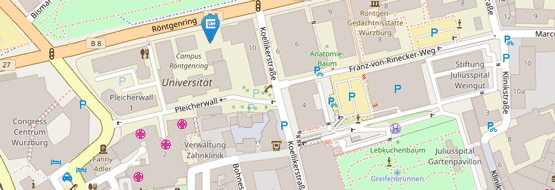

The three came to Würzburg early this year. In the second and third semester of their four-semester master's programme, the students are working on their research projects in the laboratories on Röntgenring. Under the huge umbrella of regenerative medicine, they pursue wholly different goals.

Artificial tissues from the printer

"I work with 3D printers that are capable of combining different materials at the same time to form new structures," Naomi Paxton says. The 21-year-old student studied physics at Queensland University of Technology (QUT) in Brisbane and was interested in potential applications in medicine from early on. When she heard of the new master's programme "Biofabrication", she had been all for it. The possibility to use a new technology to change the world and the lives of people had been the most exciting prospect for her.

Now she is spending the week in the labs of the Würzburg biofabrication specialists where she is making 3D printers produce ultra-fine tissues from a special polymer. These structures have hydrogels embedded in them that contain various cells and proteins. Paxton's goal is to breed artificial tissues that could be used in humans in the future – for example to replace destroyed cartilage in the knee joint. A lot of factors have to be observed in this process as the student explains. The hydrogel must not be too solid or too liquid. The cells must be able to grow and proliferate in the gel. And of course, the entire structure has to be biocompatible.

Structures that change their form

Sammy Florczak is thinking and working one step ahead. Because he found his physics studies too theoretical, he had been looking for a master's programme with direct application relevance and found the Biofab programme. Now his research activities focus on the so-called 4D printing. The fourth dimension in this case is a selective variability of the printed tissues. "For example, you can develop structures that change their form when a lower voltage is applied," he explains. Artificial muscles are another potential field of application – however one in the far future.

He believes that Würzburg is the ideal site for his research: "They have printers here that are unique in the world," says Sammy Florczak. The university owes this top position among others to Professor Paul Dalton who has been teaching and researching at the University of Würzburg since 2014. Dalton is one of the leading pioneers in the field of Melt Electrospinning Writings – a technology comparable to an ink jet printer. Instead of ink, however, a polymer melt passes through a nozzle to be applied on a carrier as an ultra-fine thread and spun to structures tailored to the desired application site. Dalton has substantially contributed to establishing the Biofab master's programme and now supervises the new course of study as well as the students in Würzburg.

A signpost for destroyed nerves

The Melt Electrospinning Writings allow the Würzburg scientists to produce even the most delicate tubes in their labs. Erin McColl is working on such tubes during her research semester. The young engineer has specialised in robotics and already built 3D printers as a student at QUT to custom-print parts for clients from the industry, for artists and other students. She enrolled in the Biofab programme, because she wanted to combine robotics and medicine.

The tubular lattice structures Erin McColl manufactures are to serve as a kind of "signpost" for nerves. "When nerves are severed as a result of an accident, the ends try to grow back together," the student explains. However, they usually do not know where to find their matching counterpart. In the future, custom-tailored tubes could serve as mechanical scaffolding that guides the cells to grow in the desired direction.

The three students consider their relocation from Brisbane to Würzburg as a major opportunity. Even though the number of scientists researching in the field of biofabrication in the world is relatively low, they are nevertheless a "global community". The course of studies in Würzburg gives them the opportunity to become a part of this community.

The "Biofabrication" master's programme

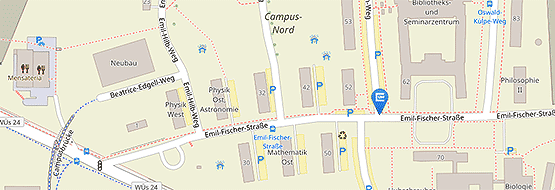

The worldwide first international "Biofabrication" master's programme comprises four semesters and is jointly offered by four universities from Germany, Australia and the Netherlands. Students that enrol in Würzburg learn the basics of tissue engineering in the first semester in courses ranging from chemistry to material science. After that, they go abroad: For two semesters, the master students do a research internship at one of the partner universities in Australia to write their master thesis once back in Würzburg in the fourth semester.

Applicants for the programme are expected to have knowledge of chemistry, physics, biology, medicine, robotics and computer science among others. Accordingly, graduates from these disciplines can apply for a place in the new master's programme. A programme with a strong research focus and lots of laboratory work is waiting for them.

Contact and information

The offer is part of the programme "EU-Australia Encounter". For more information and eligibility requirements, please contact Prof. Dr. Paul Dalton (master.biofabrikation@uni-wuerzburg.de)

For more information, visit https://www.chemie.uni-wuerzburg.de/studium/biofabrikation