A cartilage made in Würzburg

12/16/2025On 11 December 2025, the first cartilage transplant produced at the University Hospital of Würzburg was on its way to implantation. This involved several stages of quality control.

On a scale of one to ten, the tension on this Thursday at 9 a.m. was a good eight, says Sebastian Häusner, Head of Quality Control in Dr. Oliver Pullig's working group at the Chair of Functional Materials in Medicine and Dentistry at the University Hospital of Würzburg (UKW). On 11 December 2025, he and the team from Würzburg sent a cultivated cartilage on its way to implantation.

The researchers cultivated the cartilage from a patient's nose to treat his knee joint osteoarthritis. The cartilage transplant is to be implanted in a patient at a participating clinic in Europe within 24 hours. "This increases the pressure," says Häusner, "because the patient naturally expects a safe and effective implant."

The cartilage was cultivated as part of the European clinical ENCANTO study and is the first of its kind within the programme. ENCANTO stands for "Engineered Cartilage from Nose for the Treatment of Osteoarthritis" (artificially produced cartilage from the nose for the treatment of degenerative joint disease). A total of 150 patients are to be recruited at eleven clinical centres in various European countries. The Würzburg working group "GMP-compliant ATMP development" is producing the implants together with a team from Basel. To do this, it takes cartilage cells from the patient's nasal septum, multiplies them in the laboratory and cultivates them on a structuring collagen matrix to form new cartilage tissue.

This is then inserted into the knee joint to regenerate the cartilage. The aim is to alleviate the pain of patellofemoral osteoarthritis, improve joint mobility and enable joint-preserving therapy instead of permanent joint prostheses.

The transplant is sterile and free from contamination

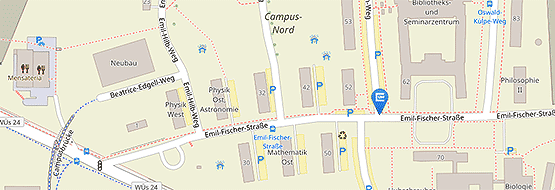

The cartilage grows for a good four weeks in the clean rooms of the GMP stem cell transplant centre under the direction of Professor Matthias Eyrich. GMP stands for "Good Manufacturing Practice" and comprises rules and regulations for quality assurance in the production of medicinal products and medical devices.

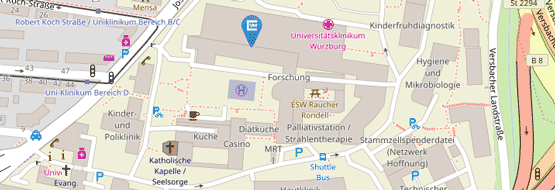

"You can judge cartilage activity quite well in the Petri dish when the tissue warps on all sides. But of course we need tangible proof," says Häusner. Microbiological monitoring under the direction of Dr. Heike Claus at the Institute of Hygiene and Microbiology has already turned out positive. The cartilage transplant is sterile and free from contamination and can therefore be safely implanted in the patient. But how did the cells develop?

Living cells are needed

To check this, Häusner and technical employee Eva Baumann collect a tissue sample from the clean room laboratory alongside the transplant and take it to the Institute of Pathology at the University of Würzburg, headed by Professor Andreas Rosenwald, which is located next door. There, the sample, which bears the name "Paula", which refers to all cartilage transplants from the ENCANTO study at the UKW, is cut into several slices four to eight micrometres thick. Dr. Dr. Elena Gerhard-Hartmann receives one of these slices. The pathologist examines the viability. How alive are the cells? Elena Gerhard-Hartmann gives the green light. Sebastian Häusner's tension drops by one point on the scale.

The final quality control

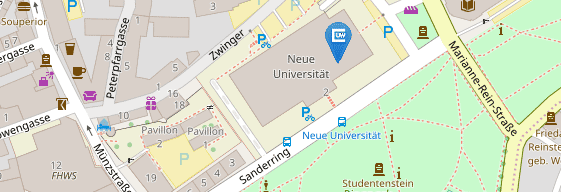

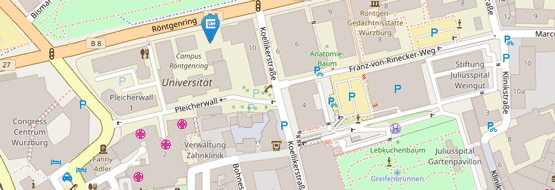

But the transplant cannot yet be released. The journey continues by taxi from Grombühl to the Chair of Functional Materials in Medicine and Dentistry at Röntgenring. Here, the tissue architecture and cell morphology are assessed. To do this, Eva Baumann stains special proteins, known as proteoglycans, in the cartilage. These give the cartilage tissue structure, elasticity and shock absorption. The more intensively the sample is coloured red, the more of these proteins are present and the better the quality of the cartilage. The cell morphology is also examined.

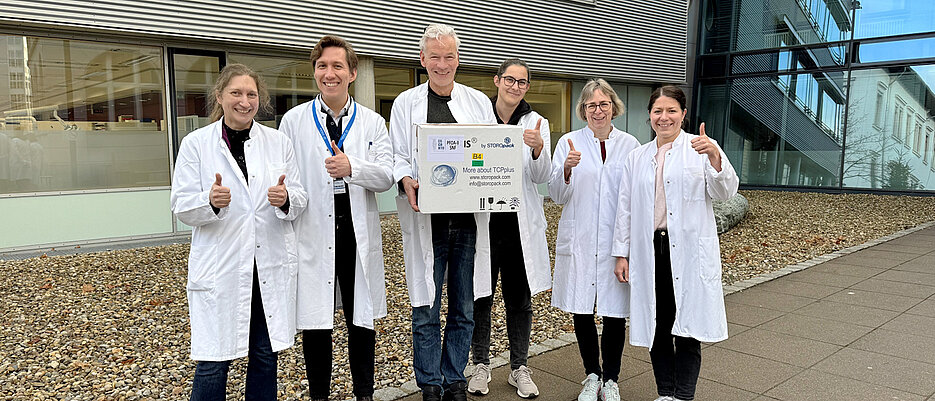

"It remains exciting until the last second," says Sebastian Häusner. Now he and Eva Baumann have to analyse the sample independently of each other. Only a high Modified Bern Score means that the cartilage fulfils ENCANTO's strict quality requirements. Then comes the relief: the sponsor in Basel and the orthopaedic surgeon on duty at the patient's clinical centre can be informed that the transplant is on its way. The patient does not know whether they are in the intervention group or the comparison group and will receive a collagen matrix without cartilage cells from their own nose.

Cartilage replacement "made in" Würzburg

Sebastian Häusner's tension eases. And an entire team breathes a sigh of relief with him. "The success of the N-TEC is based not only on the very good international collaboration, but also on the excellent local collaboration on site," emphasises Oliver Pullig. "From the diagnosis of the tissue by the pathology department and microbiological monitoring by the hygiene department to the work in the clean rooms of the GMP stem cell transplant centre - the cartilage replacement produced here is a genuine product 'made in Würzburg'." It is precisely this close networking of the clinical and university centres that forms the backbone of scientific and clinical progress at the UKW.